About FULFLEET®

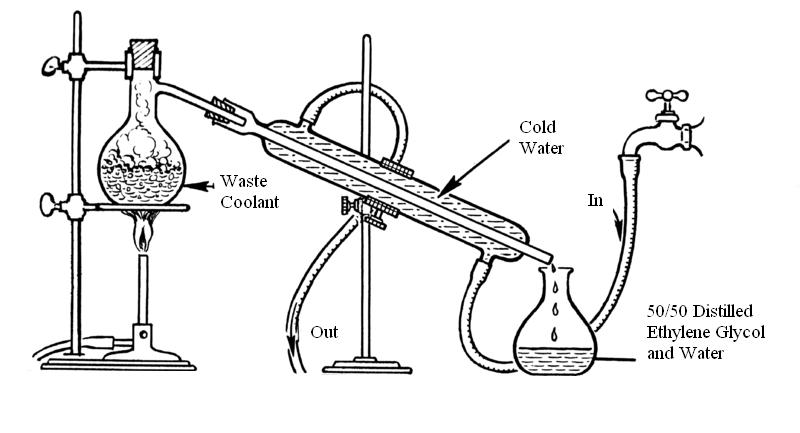

FULFLEET® uses a proprietary distillation process to make its antifreeze products. Coolant Distillation is the method of boiling used coolant, turning glycol and water into vapor, re-cooling the vapors back into a liquid and collecting this new liquid.

*For explanation purposes only.

Through our own patented process, we produce a crystal clear liquid containing distilled ethylene glycol and distilled water. We then combine this liquid with the appropriate high quality additives (Penray & others) to create remanufactured 50/50 pre-mixed antifreeze. From this process, we can efficiently separate 97% of usable product, from a used coolant sample. The paste-like 3% left behind is then properly disposed of at local waste management facilities according to local and state regulations. What’s more, not only does our advanced process reclaim glycol, it reclaims pure distilled water simultaneously. While our competition must run water through an additional, expensive process to “make” water, our process efficiently recovers both!

Our coolants meet or exceed the same strict industry standards as virgin coolants. Our products have been lab tested and meet the specifications for ASTM D-6210 (ASTM International is a global standards setting organization).